Retrofit Guide: Strengthening Server Racks with Stiffeners and Beams

Are Your Legacy Racks Keeping Up?

Legacy server racks were never designed to handle the weight of today’s equipment. GPU-heavy servers, dense storage arrays, and massive UPS systems can easily exceed the 1,200 pound limits of older infrastructure. The result is strained frames, compliance issues and increasing risk of downtime at the worst possible moment.

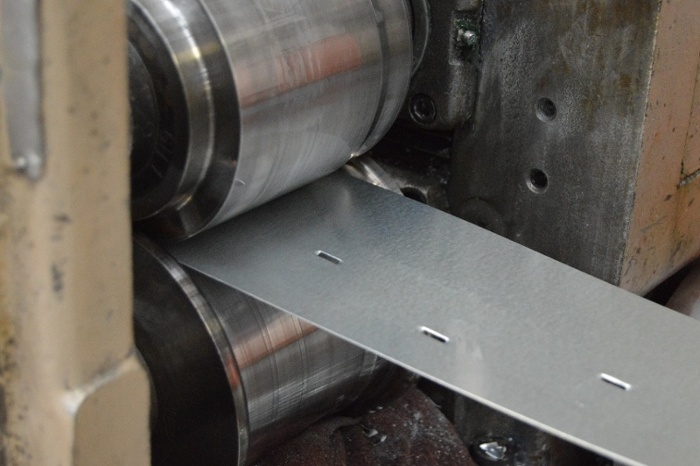

Full replacement might seem like the answer, but forklift swaps, hours of recabling, and the extra costs can make it an unrealistic choice. A smarter path is retrofitting with roll formed stiffeners and reinforcement beams. This guide will walk you through why retrofitting is often the better choice, what challenges it solves, and the key benefits you can expect from modern roll formed solutions.

Why Retrofit Beats Full Replacement Every Time

When racks fail, the consequences are more than inconvenient. Broken or underperforming racks in data centers, warehouses, or industrial environments lead to downtime, complicated moves of sensitive equipment, and unexpected costs. On top of the direct costs for new equipment and installation, businesses risk data loss, reduced productivity, and project delays.

Retrofitting helps you avoid these issues by strengthening your existing racks without tearing everything out. By adding roll formed stiffeners and reinforcement beams, you can extend rack life, increase performance, and reduce operational headaches. The benefits include:

- Cost savings: Avoid the expense of new racks and major installations.

- Minimal downtime: Retrofit components can be installed during maintenance windows, limiting disruption.

- Sustainability: Reinforcing instead of scrapping reduces waste and promotes greener business practices.

This approach keeps your equipment secure and organized without forklift swaps, extended outage windows, or recabling nightmares.

Common Rack Challenges Retrofits Solve

Aging infrastructure comes with its own set of obstacles. As demands increase and equipment becomes heavier, racks and enclosures face more pressure than ever. Compliance standards are stricter, and even small inefficiencies in alignment, airflow, or cable management can ripple into safety and performance concerns.

Traditional reinforcement methods often make things worse by adding bulk or distorting frames. Retrofitting with roll formed stiffeners solves these challenges with precision.

Load Capacity Limits

Hat channels and box beams can boost rack capacity by 20–30%, supporting today’s heavier equipment.

Seismic & Code Compliance

New IBC and OSHPD requirements need structural resilience in high-risk zones. Welded add-ons can distort frames or void warranties. But, roll formed bolt-on profiles maintain compliance without damage.

Alignment & Tolerances

Angle iron fabrications rarely achieve the straightness needed for smooth rail engagement. Roll forming achieves repeatable precision, allowing for hot-swap reliability.

Airflow & Cable Management

Bulky reinforcement kits block airflow and cable channels, raising temperatures and complicating maintenance. Slim roll formed stiffeners maintain cooling performance and preserve cable accessibility.

Building Smarter Infrastructure

By reinforcing instead of replacing, you are not only saving money. You are also future proofing your infrastructure. Roll formed stiffeners offer the strength, compliance, and efficiency needed to keep pace with today’s high demand environments, all without the operational headaches of a full overhaul.

|

For more strategies on building stronger and more efficient racks, read our Guide to Data Center Rack Design & Infrastructure. |

Benefits of Roll Formed Stiffeners and Beams

OEM Roll forming is ideal for producing long, precise profiles with complex features at scale. For stiffeners and beams, it offers:

- Strength-to-Weight Efficiency: HSLA steel allows thinner parts with equal or greater strength, reducing material usage and weight.

- Inline Embossing: Integrated emboss features improve load distribution without welding, increasing performance and durability.

- Built-in Features: Pre-punched holes, notches, and slots streamline bolt-on installation, eliminating costly secondary operations.

- Durability: Roll formed steel stiffeners resist corrosion, impact, and daily wear, providing long-term structural integrity.

Unmatched Cost and Lead Time Advantages

Beyond structural benefits, partnering with a roll forming manufacturer also accelerates timelines and reduces costs. It’s a bonus if they have a large tooling library, so new dies won't have to be produced.

In addition, roll forming has a lower scrap rate output than other manufacturing processes, which is a huge advantage when using high-value steels. Continuous roll forming also supports high volume production runs – and typically with shorter lead times compared to weldments or fabricated kits.

Cultivating a More Resilient Future

By strategically implementing bolt-on roll-formed stiffeners and beams, you can significantly extend the life and enhance the performance of your existing infrastructure. This approach avoids the disruption and expense of a full rack replacement, reinforcing your operational resilience and optimizing your investment for the future.

Partner with a Roll Forming Expert

Selecting the right manufacturing partner is crucial for the success of your retrofit project. Dahlstrom Roll Form brings over 120 years of manufacturing expertise, standing as one of the oldest and leading roll forming services globally. When you partner with Dahlstrom, you benefit from:

- Unwavering Quality: Dahlstrom's facility has maintained ISO 9001:2015 certification since 1995, demonstrating a commitment to world-class quality management systems. Their quality system metrics are comparable to companies ten times larger.

- Reliable Delivery: Dahlstrom prides itself on a 99.5% on-time delivery rate and a remarkably low defect rate of less than 4,000 PPM (parts per million), which is well below the four sigma level of 6,210 PPM.

Beyond exceptional manufacturing, Dahlstrom offers a comprehensive suite of services designed to optimize your supply chain.

These include:

- Vendor-managed inventory (VMI) systems, a core strength since 1996, ensuring just-in-time (JIT) supply based on your actual demand, minimizing inventory holding costs and freeing up resources.

- Custom packaging solutions that can help consolidate shipping costs and prevent in-transit damage.

- Quarterly reviews offer full transparency on detailed consumption data, raw material pipeline status, market price trends, business forecasts, and design changes, ensuring a truly integrated partnership.

- Raw material sourcing, with Dahlstrom typically buying the raw materials 95% of the time, to ensure materials meet tooling criteria and optimal performance. They actively monitor the market to provide informed material buys and pass savings along.

- Collaborative engineering design from the very start of your project to ensure parts are produced efficiently and economically.

- In-house powder coating and other minor assembly/washing services further streamline customer processes.

Ready to explore how roll-formed retrofit solutions can strengthen your infrastructure? Contact Dahlstrom Roll Form today for expert guidance on rack reinforcement solutions!

You May Also Like

These Related Stories

Warehouse Storage Racks and Conveyors: Consider Roll Forming

6 Important Factors in Manufacturing a Solar Racking System