Why Your Roll Former Needs Better Manufacturing Shipping Solutions

Customers don't ask for much. All they want is the right product at the right price, delivered on time and free from defects. That doesn't seem unreasonable, but many manufacturers struggle to hit all four points simultaneously. Hitting all four on a consistent basis is harder still.

Aggravating, isn’t it?

Below we'll give six examples of how your roll forming manufacturer can improve on-time delivery and packaging. Don’t let your roll forming partner overlook these important manufacturing shipping processes as it processes your order. Take it from the guys with a 99.5% on-time delivery rate.

6 Manufacturing Shipping Problems & How Your Roll Forming Partner Can Fix Them

Metal roll forming manufacturing companies set out to be late. Delays happen when things don't go according to plan.

Packaging and delivery is a sore spot for many OEMs dependent on a big batch of components. For some reason, this bottleneck has gone unaddressed for far too long.

Here are six issues (and solutions) we’ve personally tested (and our OEM customers have loved):

Issue #1: You’re Not Even Using a Roll Forming Manufacturing Business

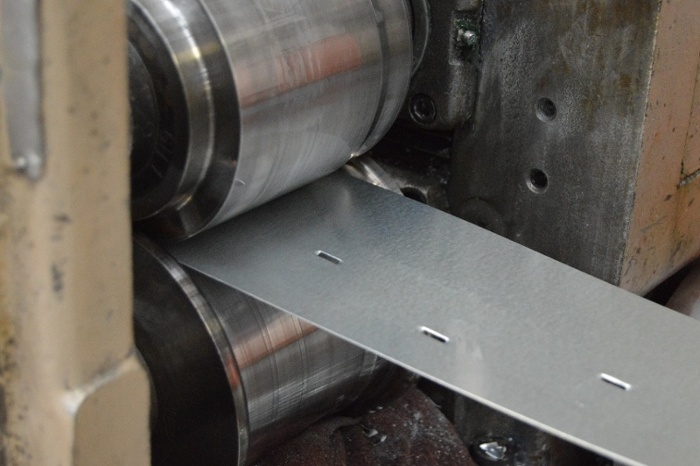

Picture a pair of rollers shaped so one matches the other. Now feed a metal strip between them: it comes out with a cross-section the same as the surface of the rollers. The process is similar to extrusion in that it produces long metal forms that get cut to length, but without the huge press tonnages. It's also a better way of forming very thin-wall shapes, like say gutters, and it's possible to incorporate other operations like hole piercing in-line, saving run-time costs.

That is custom roll forming. It’s a highly repeatable setup, and if your lead times need shortening, it may be the manufacturing process itself that needs to change.

Issue #2: Your Manufacturer Performs Terribly

How seriously does your metal manufacturer take its lead time promises? Enough to monitor and measure performance closely?

In 2021, our on-time delivery rate was 99.5%. The benchmark is 70%-80% in metal manufacturing. So we did better than most.

The same dedicated approach should apply to quality. Does your manufacturing painstakingly measure parts-per-million (PPM) defect rates?

Our PPM defect rate was 3,827 in 2021. To put that in the context of Six Sigma quality, we operate above 4 Sigma in our quality system.

If you’re in an environment that’s highly competitive or requires quick turnarounds, a contractor with poor numbers may be worth ditching.

Issue #3: Your Manufacturer Isn’t Lean

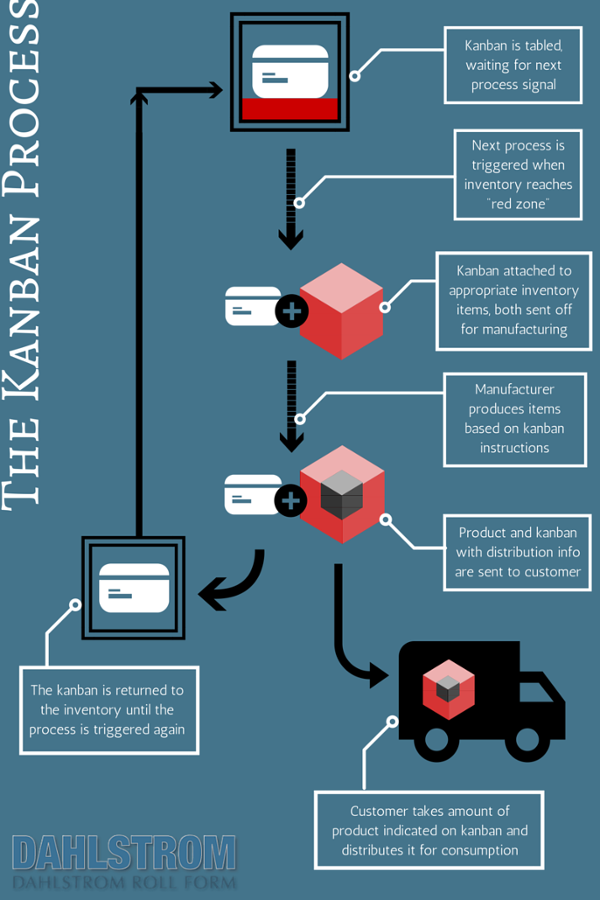

Most manufacturers have heard about kanban inventory management, but not all have applied it to its full effect in roll forming. In brief, kanban is about using demand to initiate production, rather than working based on a forecast, (which is usually wrong!).

Using a kanban replenishment system helps prevent unnecessary deliveries and overcrowded manufacturing spaces for both the customer and supplier. Instead, we ask you to give us weekly counts of unopened bundles, and we replenish your stock to pre-agreed levels. Easy, right?

Issue #4: Packaging Isn't Their Strong Suit

Boxing parts so they “nest” is a great way of consolidating packaging costs and getting more in the truck. (Which also lowers shipping costs!)

Getting creative about dunnage design can also reduce or even eliminate in-transit damage – a quality gain!

The packaging process is unique to each component and based on a variety of factors, and your roll former should treat it as such. Your roll former should spend money on packaging, period! Nothing is worse than damaged products in the field, which causes exponential problems for the entire supply chain.

Issue #5: You Like Sustainability

Sustainable and returnable packaging is growing in popularity.

If you and your manufacturer have gone to the trouble of arranging for custom packaging materials, why toss them after a single use? We've worked with customers on returnable solutions that reduce waste and lower total costs.

Example: Some customers will send back empty, reusable steel containers to us. It triggers production, and we happily ship them back full to eliminate packaging footprint and cost for recurring customers. (Just make sure you send us the crates back!)

Issue #6: Your Partner Isn’t Fully Leveraging Roll Forming Efficiencies

With roll forming, there are all manners of ways to combine manufacturing processes.

If your vendor cuts out secondary stops on the line, you reduce queuing and handling, which can boost delivery performance. A great example of this is our new in-line UPC label application. We developed an intermittent sticker applicator for automated component labeling. (Dealing with the lubricant film present on each component was quite a challenge!)

This is a great example of continuous improvement at work, as this task previously fell to human laborers at a separate station.

What’s Your Delivery Horror Story?

Your roll forming manufacturer should understand the importance of having a product arrive as promised -- on time and in one piece. That means constantly looking for ways to improve delivery performance until that 70-80% benchmark is a distant memory.

We've showcased six examples here. If you’d like more advice on how we can customize your packaging and delivery needs, get in touch.

(Editor's note: This article was originally published in February 2019 and was updated in December 2021.)

You May Also Like

These Related Stories

Keep Roll Forming Costs Under Control With Kanban Inventory Management

Cut Lead Time & Red Tape With Roll Forming Tooling Manufacturers